Dr. Jung-whan Baek (H Plastic Surgery)

However, such methods do not offer permanent solutions. Surgeries using traditional implant materials do not allow creation of an implant with a customized fit to the patient’s facial structure. They are also prone to many complications including migration, displacement, and boundary protrusion, etc. However, 3D printed implants allow customization of the implant form and are free from problems of displacement or misfit.

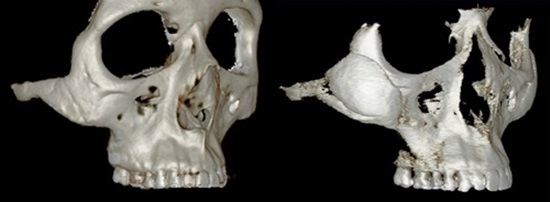

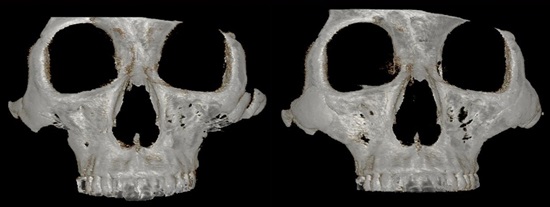

Image 2-2. Diagonal 3D CT before and after reconstruction.

The right image of <Image 2-2> shows correction of the 45° defect with a 3D Fit implant. The 3D CT images show a boundary of the implant caused by the discrepancy between CT scanner and printer as well as the minimal thickness of the implant but the error is less than 1mm and the fit of the implant was smooth.

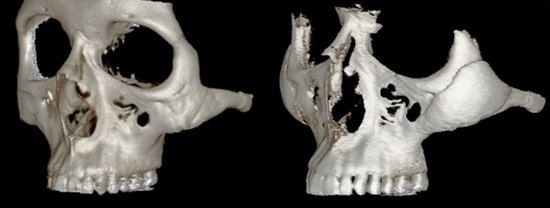

Image 2-3. Diagonal 3D CT before and after reconstruction.

[Advertisement] MAGNUM(Q-switched Nd:YAG Laser) – Manufacturer: (www.i-dana.com)]

The left diagonal 3D CT image shows the adequate fit of the 3D Fit PMMA implant with the patient’s bone structure.

Image 3-1. This patient received a secondary zygoma reduction surgery due to dissatisfaction with the first reduction. Zygoma indentation was caused by a new bone resection during the second surgery.

The left before-reconstruction image of <Image 3-1> shows inferior displacement of the central bone fragment of the left zygoma due to two resections. Bone loss is also seen along the line of resection. An indentation of 45° was externally visible in the cheekbone with a naked eye.

.jpg)

Image 3-2. Diagonal 3D CT before and after reconstruction.

-To be continued