“Dr. Baek pioneered a new field in plastic surgery with his innovative method of creating a customized implant with a 3D printer.”

These days, Dr. Jung-hwan Baek of H Plastic Surgery immerses himself in 3D printing technology. A 3D printer produces a three-dimensional object that matches the 3D blueprint devised by a computer program. Dr. Baek prints human facial bone with a 3D printer and creates a customized implant using the 3D object. He has invented ‘3D fit face sculpting’ by applying 3D printing technology to plastic surgery.

“In 2012, a patient with a deformed chin visited my practice. The deformity was caused by drastic removal of bone in corrective jawline surgery. Excessive cutting of jaw bones caused deformity where the tip of the chin was severely protruding. Repeated surgeries left the soft tissues of the face out of balance with lumps and sagging in different places. The indented areas could be corrected with fat graft or fillers but drastic improvement was not to be expected. This patient got me exploring ways to restore resected jawbones.”

Lost bones are restored by using the bone from the leg or ribcage. However, this method is for functional restoration and is not suitable for an aesthetic procedure. After much consideration, Dr. Baek decided to apply 3D printing technology to plastic surgery.

“In medical school I once tried a RP (Rapid Protocoltype) model simulation before double jaw surgery. I also wrote a thesis on measuring the mandible and soft tissues with 3D CT. I had always been interested in the potential of 3D technology in plastic surgery and came to realize that 3D printing was being used to complement surgery or in simulation.”

HELIOSⅡ/LOTUSⅡ/HYPERION – Manufacturer: LASEROPTEK(www.laseroptek.com)

Scope of application of 3D fit face sculpting

Dr. Baek examined the possibility of using 3D printing in plastic surgery based on his research on the internet. He read about various attempts made throughout the world to this end and saw great potential.

“In 2013, OPM (Oxford Performance Materials) of the US produced PEKK (polyetherketoneketone), bio-engineered bone replacement material, using 3D printing. There was a case study where this material was used in a patient. Belgium’s Materialise together with Synthes were in the process of manufacturing a commercial cranium replacement using PEKK. In Korea, an otorhinolaryngologist of Samsung Medical Center was reported to have used 3D printed cranium replacement in a patient with nasal cavity cancer.”

Dr. Baek saw a potential for a new market and decided to try face sculpting using a 3D printer in November 2013.

“I changed the name of my private practice and renovated the office to start face sculpting treatment using 3D printing. At first, I focused on reconstructive surgery but as time went on, the area overlapped with cosmetic surgery. Currently, I am researching ways to replace lost jawbones using 3D printing. Short chin, middle face correction, nasolabial angle, front cheek bones, forehead, head shape, and back of the head, etc. can be corrected using this technology. In the future, I intend to apply this technology to patients with traumatic bone loss.”

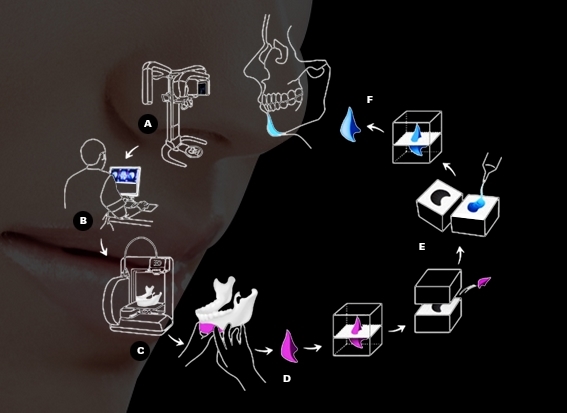

Process of ‘3D fit face sculpting’

1. After 3D modeling, manual temporary implant, mold, and final implant are created

-3D modeling of bone using CT image

-Production of replacement model to be inserted into 3D modeling

-Creation of mold based on the model

-Creation of the implant using the mold

-Sterilization of the final implant

-Surgical implantation

Image 1.

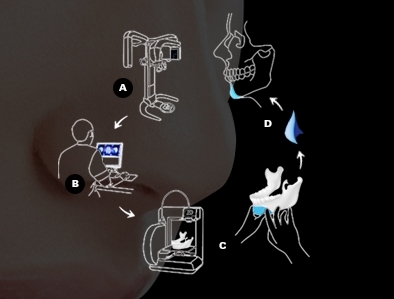

2. Create manual implant during 3D modeling & surgery

-3D modeling of the bone using CT image

-Sterilization of 3D model

-Creation of final implant (bone cement etc.) using 3D model during surgery

-After hardening, surgical implantation

Image 2.

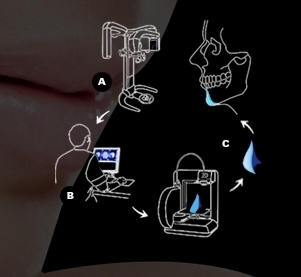

3. Creation of 3D modeling & final implant

-Creation of implant using computer imaging, simulation, and design

-Sterilization of final implant

-Surgical implantation

Image 3.

Commercial products were not customized and did not fit the patient well. This caused problems such as implant displacement after surgery. 3D fit face sculpting considers inner bone structure that is not readily visible during surgery and allows production of an implant that fits the patient’s facial structure precisely. Nonetheless, there are drawbacks to this new technology.

“As the 3D printing is still new and innovative, the cost is very high. CT imaging and implant production takes 24 hours and costs about a million won. The choice of material for the implant is another problem. The material should have proven safety to be allowed for use in the human body. Currently, there are no materials that can replace the autologous bone. I read up on the new material of PEKK closely but the printer alone costs over 2 billion won and each print costs 2 million won. To my knowledge, only five national or large research institutions around the world purchased this new technology. As the cost of PEKK is too exorbitant for a private practice to afford, I am still looking for other materials. I am planning to visit Japan soon as they developed last June calcium powder that turns into bone tissues when applied onto the bone .”

-To be continued-