Dye Laser Pumping

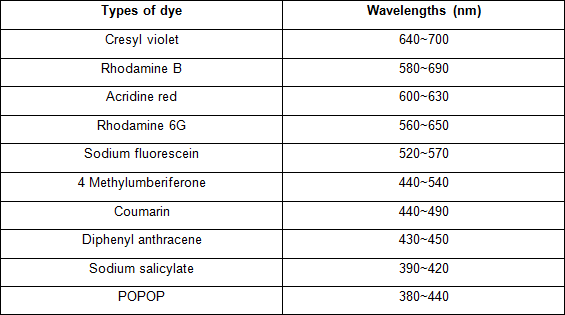

As the dye molecule and solvent have strong interactions, dense vibration and rotation levels present continuous wide band through the spreading behavior. These generally act in the pulse mode and numerous organic dyes are available to generate Laser beams in any wavelength within the visible light range. This distinguishes the dye Laser from other Lasers as it allows continuous adjustment of a wide range of wavelengths.

There are other Laser devices that also allow adjusting the wavelength of the Laser beam. However, the wavelength of incident light and that of oscillated light are different. The dye Laser internally adjusts wavelength by changing the concentration and length of dye cells or controlling diffraction grating.

Dye molecules are excited by the energy from the external light source. After Laser beam emission, the excitation level falls to the bottom through a nonradiative process. The dye can absorb or emit a wide range of wavelengths as it maintains a continuous energy level through interactions between the electron, oscillation and rotation levels. As with the solid state Laser, the light source of the dye Laser uses a flash lamp or external Laser.

As complex molecules tend to be disintegrated by powerful light, Laser pumping is frequently used for higher output despite low efficiency. The greatest advantage of a dye Laser is adjustable wavelengths, very short pulse duration and very small spot size.

Solid State Dye Laser

The dye Laser uses dye as the gain medium. Dyes refer to pigments, which are dissolved in a liquid such as alcohol. On the other hand, the dye can be also used in a solid state by injecting it into plastic or high- molecule organic compounds. Lasers that use a solid state dye are called solid dye Laser. Traditional dye Lasers used solvents such as alcohol and required circulation elements such as a pump or filter.

This created a larger system. To overcome this drawback, efforts were made globally to develop a tunable solid medium that replaces dyes. Solid-state Laser medium is more durable with a very long lifespan. It also allowed the Laser system to be more compact. Recent technology enables the use of diode as the pumping source, which leads to a high output and a wider range of wavelengths.

Solid dye Lasers has the wide tunable Laser range (near-infrared to ultraviolet) of traditional dye Lasers and can be manufactured at a low cost. Therefore, they can compensate for the limitations of both liquid dye and solid state Lasers. As the device can be made compact, it can effectively replace liquid dye Lasers for low-output spectroscopic research and irradiation source. It can also easily adjust the tunable Laser range through switching to solid dyes with different oscillation range.

[Advertisement] Ultra Skin/Pastelle – Manufacturer: WONTECH(www.wtlaser.com)

Advantages and Disadvantages of Dye Laser

One advantage of a dye Laser is that the dye material is naturally homogeneous, which does not require manufacturing a completely homogenous solid. It is also relatively easy to change the dye form which is used as a Laser medium. Heat is generated during oscillation but Laser medium is continuously replaced for easy cooling and short pulse or small spot size are possible.

A disadvantage is that maintenance can be complicated due to the liquid Laser medium. Also, using another Laser for pumping source complicates the Laser system. As the dye has a short life, it needs to be replaced continuously to maintain a consistent output, which increases the maintenance cost. As the dye is toxic and uses a flammable solvent, the Laser system produces dangerous waste material. This can be a regulatory basis for banning marketing of certain devices based on the global RoHS standards.

-To be continued